Projects

Apple Watch Charger

Designed and 3D printed portable Apple Watch charger and case which utilizes an Adafruit board and miscellaneous electronic components.

View Project

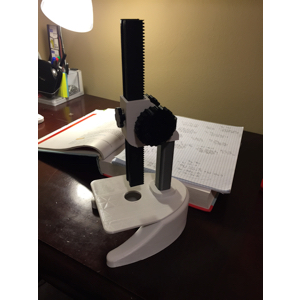

Microscope

Designed and 3D printed microscope with 100x magnification which utilizes disposable camera lenses.

View Project

Radio Controlled Aircarft

The team, The Do Do Birds, was tasked with the objective to design and develop a radio controlled aircraft driven by a small electric motor by the fictional company, Redienhcs Corporation as part of a group project.

View Project